|

Jacking pipes are used to produce piping

sections with Microtunneling technique using GRP Jacking Pipes.

This

method of laying designed to overcome obstacles represented by main

roads or highways, railway tracks, canals, buildings and other

structures that are located on the pipeline route is now universally

used to make whole hydraulic systems where traditional methods are not

allowed.

In this application, where the commonly used material is concrete,

GRP pipes are particularly appreciated for:

-

the hydraulic features that in this case also allow for significant

reductions in the design diameters resulting in savings in excavation

volumes, excavation equipment and transport costs

-

the great structural

strength that allows considerably smaller thicknesses than concrete

-

the

lightness (compared to concrete)

-

the very low external roughness of the

pipe walls that facilitates digging operations

All features that allow

the use of smaller push force during work and, if necessary, longer push

stretches.

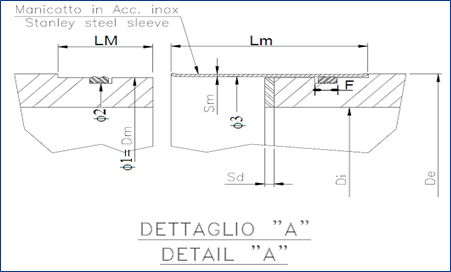

JOINT SYSTEMS FOR SARPLAST JACKING PIPES

Each pipe bar has a milling

on both ends that allows the housing of the sleeve made of AISI 304

steel. Within this milling, the seat of the sealing gasket is normally

made of EPDM or NBR material. The gasket, depending on the application,

can be made with multiple lip profiles, O-rings or alternative

geometries.

The outer diameter of the pipe and sleeve does not have

geometry discontinuities, in order to avoid any interference during the

advancement of the pipe.

BENTONITE INJECTION NIPPLES Where necessary, the pipe may be equipped

with injection threaded nipples in AISI 304. Such details, normally no.

3 per bar (120 ° to each other) are inserted into the wall of the pipe

and sealed by means of a special resin.

|